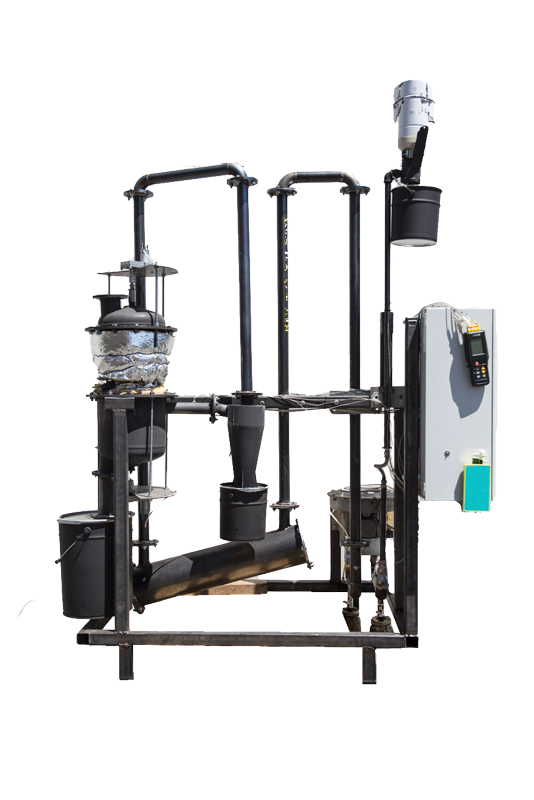

A technology used to convert solid fuel to synthetic gas (syngas): an important source of clear, renewable energy.

Fuel is obtained through pyro-gasification process applied to biomasses: waste materials easily available at a low cost or that would even require treatment before disposal (such as, among others, prunings, shells, wood by-products and food waste).

The syngas is then used in cogeneration and trigeneration plants which do not produce waste but release CO2 (absorbed by plants) and biochar – the only by-product – widely used in agriculture.

More specifically, we have designed and manufactured the following parts of the reactor:

> sensor acquisition and control actuator systems;

> an automation board, which collects signals and activates the actuators;

> a PC-based supervisory system, which collects data and makes them usable for remote assistance and functional controls through the cloud.

Thanks to an optical system with frequency sensors and LED lighting, this sorter improves the efficiency of defect detection – and of the selection mechanism therefore – on large quantities of product. Indeed, it can discern even the slightest difference in tone.

- Once inserted into the loading hopper, each product is controlled individually by the optical system

- Depending on the signals detected, the management software controls the pneumatic device

- The device physically divides the products to be discarded from those recognized as compliant

- Compliant products follow the flow until they reach the discharge hopper

Thanks to an optical system with frequency sensors and LED lighting, this sorter improves the efficiency of defect detection – and of the selection mechanism therefore – on large quantities of product. Indeed, it can discern even the slightest difference in tone.

- Once inserted into the loading hopper, each product is controlled individually by the optical system

- Depending on the signals detected, the management software controls the pneumatic device

- The device physically divides the products to be discarded from those recognized as compliant

- Compliant products follow the flow until they reach the discharge hopper

We collaborated with U&O to create a high-technology exoskeleton (pelvic belt and lower limbs) to be used in rehabilitation robotics to help people with limited mobility.

It represents an innovative therapeutic approach and is therefore one of the most advanced medical devices available today.

Its minimal and ergonomic design, together with its low weight and long battery life, makes it more comfortable and less invasive than previous technologies.

For further information, please visit https://uando.it/